485x485x500 mm

Tool Racks

500°C - 3D Printing T°

200°C - Bed T°

150°C - Enclosure T°

ROBOTIC 5 AXIS

FILAMENTS & PELLETS

MULTI-MATERIALS

AUTOMATED

ADJUSTABLE

EVOLUTIONARY

THE

PERFECT

FIT

In order to succeed, the industry must shift towards printing ready-to-use functional parts with unrivaled performance in a highly productive manner.

Our innovative machine takes 3D printing a step forward by manufacturing functional parts without any compromise.

Our hybrid and ultra-functional printer allows you to manufacture complex, precise, functional and scalable parts in nearly any industrial-grade materials for a perfect fit rendering.

We automatized the process from end-to-end in order to provide a seamless experience that allows time efficiency, resource optimization, and industrial value.

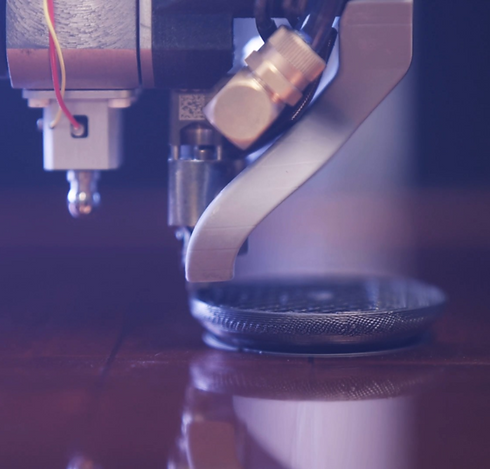

SIMULTANEOUS ADDITIVE AND SUBTRACTIVE OPERATIONS

Printing and subtracting are carried out automatically, without the need for human intervention, resulting in post-processing operations layer by layer for precise, repeatable and high-quality surface finish parts.

ROBOTIC 5 AXIS MILLING

The 2 additional rotational axis allows you to post-process surfaces unreachable with traditional printers and remove the supports, for complex designs and ready-to-use parts.

FILAMENT AND

PELLET HEADS

Our 2 extrusion heads grant you access to pellet and filament materials but also enables the printing of bi-materials parts for an unlimited type of industrial parts.

MULTIPLE

HIGH-PERFORMANCE

MATERIALS

4Shift supports 60+ materials empowering you to choose from a wide range of materials between polymers, composites, ceramics, and metals.

COHESIVE

BED SHEETS

Our different bed sheets ensure optimal adhesion of the first layer, whatever the material you want to print.

HIGH TEMPERATURE PRINTING

4SHIFT is able to extrude materials up to 500°C allowing the extrusion of high-performance materials and boosting printing speed.

AUTOMATED

TOOL CHANGER

The 4SHIFT's proprietary system allows additive and subtractive tools to be changed in seconds in a hands-free process for better condition control and resource optimization.

HEATED ENVIRONMENTAL PRINTING

The printing enclosure heats up to 150°C to decrease warping and layer delamination for better quality parts and increased mechanical properties.

TECHNICAL SHEET

Bed surface

485 mm (L) x 485 mm (W) x 500 mm (H)

External dimensions

1800 mm (L) x 1400 mm (W) x 2625 mm (H)

Number of tool positions

4

Tooling changer

Automatic proprietary system

Calibration

True bed leveling

Reliability

Resuming process after power failure

End of filament detection

Nozzle size

from 0.2mm to 1.2mm

Granulometry

3,5 mm

Filament size

1,75 mm

Pellet tank capacity

7kg

Maximum milling speed

50k RPM

Thermic environment

Heating bed: maximum 200°C

Heated enclosure: maximum 150°C

Liquid tool cooling

Connectivity

Ethernet

Build area

Pneumatic bed suction

Choice of materials

Security

EEC certified

Filtration system (HEPA 13)

Door opening detection

General emergency stop

Control

22-inch touch screen

Computer and embedded software

Complete control interface

Software

Hybrid proprietary software

AN UNPRECEDENTED CHOICE OF MATERIALS